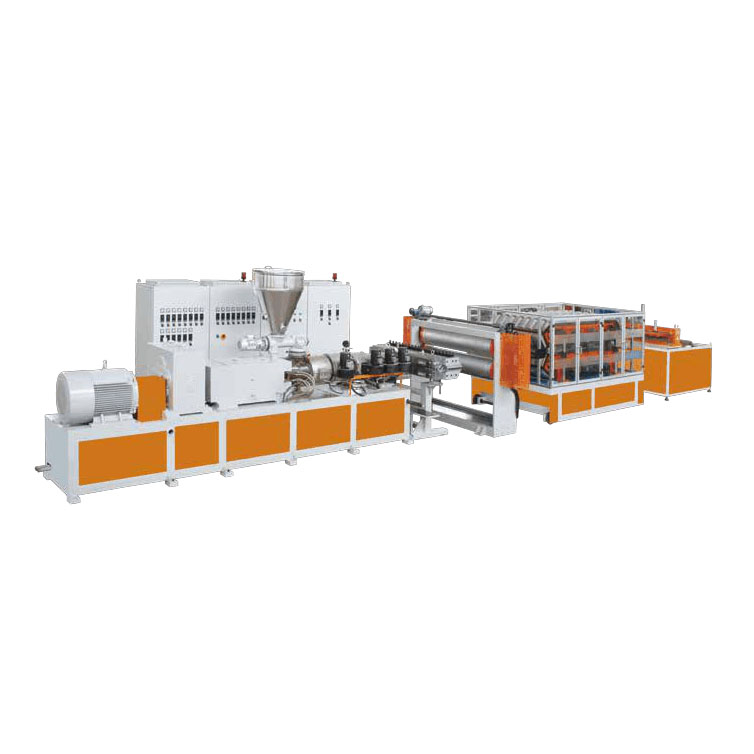

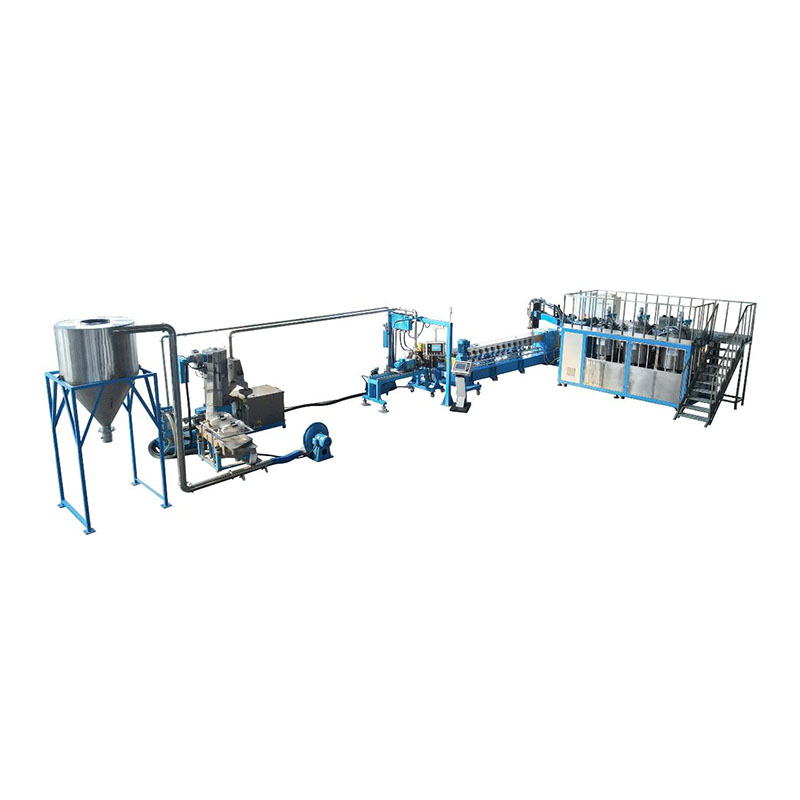

PC hollow sheet/U-shaped/U locked sheet extrusion line

PC hollow sheet/U-shaped/U locked sheet extrusion line consists of single screw extruder, gear pump + hydraulic screen changer, vacuum setting table, first-stage tractor, oven, corona treatment, cooling table, second-stage traction, and cutting edge and cut to length, composed of unloading table.

Introduction Of PC Hollow Sheet/U-Shaped/U Locked Sheet Extrusion Line

Jwell PC Hollow Cross Section Plate extrusion line adopts different screw designs and mechanical configurations to produce various PC and PP hollow plates specifications. The maximum width that can make is 2300mm, and the thickness is from 2mm-12mm.

1. Extruder: The screw and advanced temperature control system's unique design ensures an excellent plasticizing effect of raw materials and stable extrusion with high output.

2. Screen changer: The hydraulic quick screen changer is selected to make the screen change process fast and effective. The double station and particular sealing structure ensure the stable operation of the screen changer.

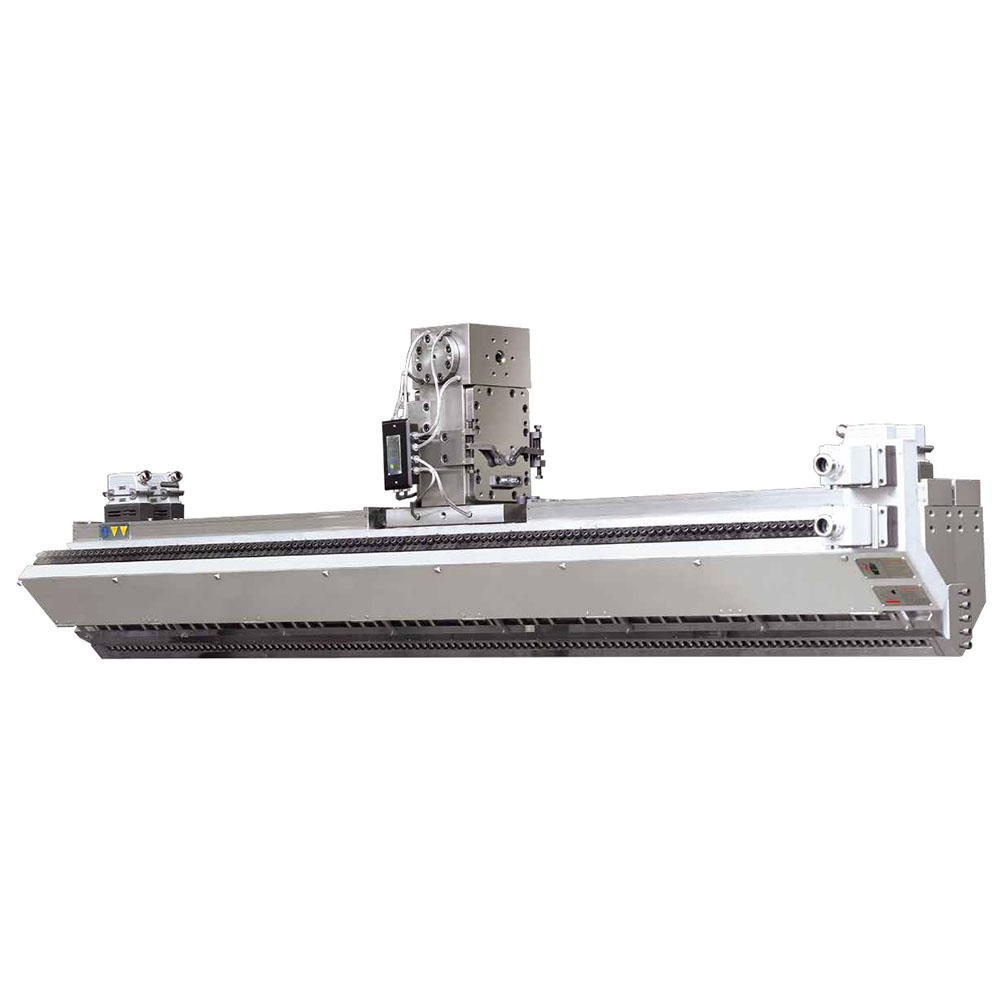

3. Mould: The mold is made of high-quality alloy steel, with a highly portable throttling device, so that the distribution pressure of the raw material flow in the die is uniform, and the upper and lower die are differentially adjusted to ensure the uniform thickness of the upper and lower walls.

4. Vacuum setting table: the setting system is equipped with a fast heat exchange refrigeration system. And the vacuum system is effectively staggered, and the sucking distribution is even and reasonable. Qingdao hollow grid board equipment, this distribution ensures the shaping accuracy. The vacuum system is composed of two subsystems. Each subsystem is equipped with multiple three-point fixed cycle vacuum groups. Each fixed cycle carries a vacuum adjustment system and a vacuum display system to make the vacuum degree of the plate surface uniform and stable.

5. Tractors: Tractors are distributed in the first group and the second group. The first group of tractors is of high-power, large reduction ratio, and multi-roller type. It has excellent low-speed rotation performance and considerable traction, which can simultaneously and uniformly pull the plates out of the vacuum setting table. The second group of tractors cooperates to remove product stress. It is also equipped with an edge trimming device, PVC hollow grid board equipment to ensure the board's effective width and edge quality.

6. Stress eliminator: The advanced large-area conduction heating method can effectively eliminate the plate's stress and further increase the container's flatness.

7. Cutting machine: Equipped with precise instant fixed-length cutting and automatic lifting and unloading devices and special alloy wear-resistant blades to ensure the plate's quality of the cut surface. Use sawing for thick plates over 5mm.

PC Hollow Sheet/U-Shaped/U Locked Sheet Extrusion Line Main Technical Parameter

| Model | Products width(mm) | Products thickness(mm) | Designed capacity(kg/h) |

| JWS100+JWS45 | 1220 | 4-40 | 350 |

| JWS100+JWS45 | 2100 | 4-40 | 450 |

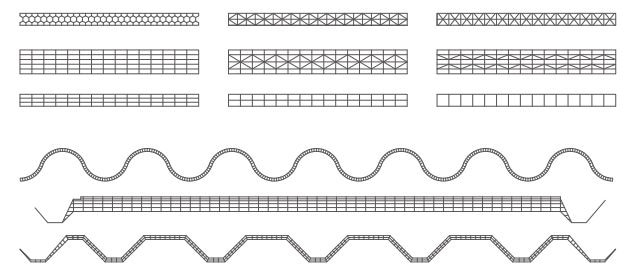

PC Hollow Sheet/U-Shaped/U Locked Sheet Extrusion Line Hollow Type

PC Hollow Sheet/U-Shaped/U Locked Sheet Application

1. Construction of sunroof in buildings, halls, shopping center, stadium, public places of entertainment, and public facility.

2. Rain shield of bus stations, garages, pergolas, corridors.

3. Transparent shields for security forces in nursery schools airports, factories.

PC hollow sheet/U-shaped/U locked sheet has light material, high strength, moisture resistance, good environmental protection performance, and secondary processing performance.

It can be processed into turnover boxes, packing boxes, partitions, liners, pads, bottom brackets, etc. It is widely used in the fields of electronics, home appliances, luggage, machinery, postal services, food, medicine, pesticides, advertising, and decoration.

FAQ

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW.

● Terms of Payment: LC, T/T.

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months.

● Number of Foreign Trading Staff:>50 People.

Yes, We own 5 manufacturing bases and sales center in Shanghai, Suzhou, Changzhou, Zhou Shan, Dongguan China.

Jwell made the first Chinese screw and barrel in 1978 in brand name Jinhailuo. After more than 40 years development.

JWELL is one of the biggest extrusion machine supplier in China with 300design&test engineer, 3000 employees.

Jwell has become the premier supplier of extrusion lines and reliable business partners. Welcome to drop in us.

Our machines taking the European standards and follow the Germany type of business, we cooperation with International famous brands Siemens Schneider Flender Omron ABB WEG Falk Fuji etc. Our company continuously imports over 1000 international first-class high precision processing equipment such as multistage machining centers, CNC lathes and CNC milling machines from Korea, Japan etc. All our processes strictly adhere to CE certification, IS09001 and 2008 quality management system. And we have 12 months quality warranty time. We testing the machine performances before each delivery. Jwell service engineers will always be here for anything you needed.

Usually it takes about 1 – 4 months depends on different machinery upon receipt of order advance payment.

Once clear your requirements and determined extrusion line is ideal for you. We will send technical solutions and Proforma Invoice to you. You can pay via TT bank transfer, LC as you like.

One. We provide both customized extrusion lines and technical solutions. Welcome contact with us for technical innovation or improvements for your future purchasing plan.

We produce more than 2000 advanced extrusion lines every year world wide.

We can send the small spare parts by air express for urgent matter. And the complete production line by sea to save the cost. You can either use your own assigned shipping agent or our cooperative forwarder. The nearest port is China Shanghai, Ningbo port, which is convenient for maritime transportation..

Yes, we support our business partners by pre-after sale service. Jwell has more than 300 technical testing engineers traveling world wide. Any cases would be responded with prompt solutions. We provide training, testing, operation and maintenance service for a life time.

Certificates

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: Other

Design, Development, Manufacture And Sales Of Intellectual Property Rights Management For Plastic Machine

2016-06-14 ~ 2019-06-13

Certified By: Other

Design, Development, Manufacture And Sales Of Plastic Pipe And Sheet Extrusion Production Line

2018-11-20 ~ 2021-11-19

Certified By: Quality Austria Training, Certification and Evaluation Ltd.

Plastic Extrusion Line

2010-01-29 ~